The powerful contribution of IHI-Sullair Air Compressor applicatie in the Automotive Industry

As a widely used general equipment in multiple industrial fields, centrifugal air compressors are essential industrial products in China's manufacturing industry. The manufacturing process of contemporary automobiles and components also has strict requirements for the quality of compressed air and the reliability of air compressors.

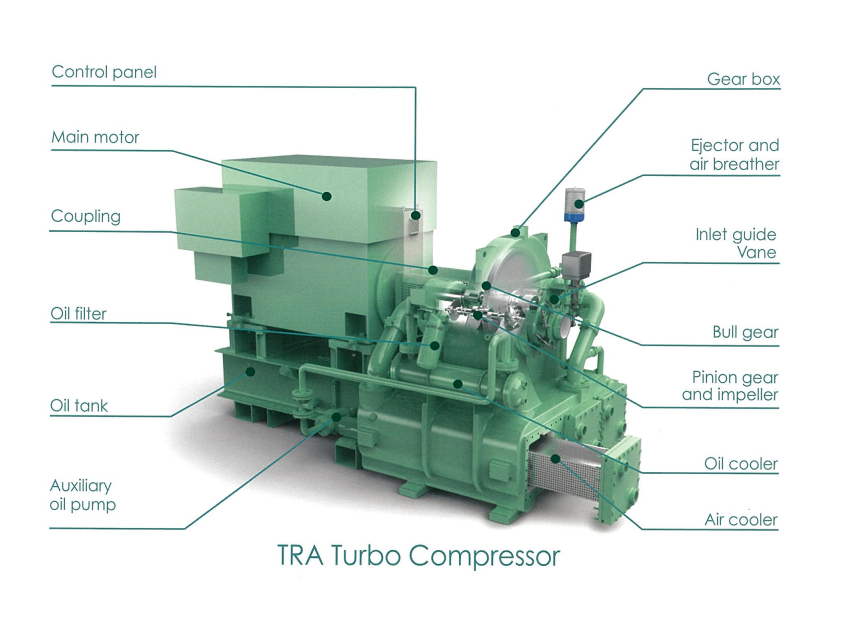

IHI-Sullair centrifugal air compressors are widely used in various aspects of automotive manufacturing due to their compact structure, reliable operation, energy efficiency, and high gas supply quality. From assembly work to painting, stamping, and body manufacturing, IHI-Sullair centrifugal air compressors are involved in every production stage; The IHI-Sullair centrifugal air compressor is designed according to API standards and can provide 100% oil-free compressed air 24/7, shining brightly in the Chinese automotive manufacturing industry and being chosen by more and more car companies.

IHI-Sullair centrifugal air compressor products use advanced PLC control system to adjust the operating mode, which can be applied to various operating conditions, scientifically and reasonably adjust pressure and flow, provide power for the pneumatic machinery of automotive enterprises, and ensure the high-precision and stable operation of these machine arms, providing strong support in multiple production stages such as welding, fixation, and assembly.

In the spraying process and offline inspection process, IHI-Sullair centrifugal air compressor provides strong assurance for the painting work of automotive companies with continuous and stable gas supply. The IHI-Sullair centrifugal air compressor has a wide range of flow adjustment range and pressure setting, which can allow compressed air to flow at high speed inside the spray gun. The paint is then drawn from the lacquerware into the spray gun through a gas pipe and sprayed onto the surface of automotive products.

The core advantages of IHI-Sullair air compressor:

① Compact volume and reasonable weight

In the working environment of the automotive manufacturing industry, car manufacturers should ensure that the size of the air compressor is suitable for the working area, in order to facilitate installation and maintenance. The IHI-Sullair centrifugal compressor adopts a compact lever mounted structure, which can meet the usage needs of various space occasions for automotive companies and save installation costs.

IHI-Sullair centrifugal compressor adopts high-quality titanium alloy impeller, which greatly improves efficiency compared to stainless steel impeller. At the same time, we adopt advanced PLC control systems with control modes such as loading and unloading, automatic dual, and full constant pressure, which can meet the production needs of car manufacturers in various situations.

② High efficiency and stability:

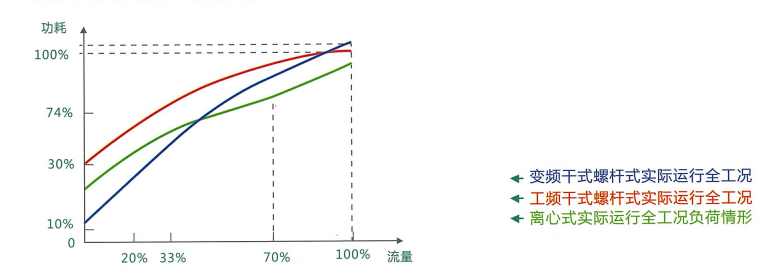

The main cost of long-term operation of air compressors is electricity consumption. Choosing air compressor products with high energy efficiency can significantly save usage costs. The IHI-Sullair centrifugal air compressor adopts multiple monitoring and protection devices, which not only protects the stable operation of the equipment, but also saves energy compared to similar centrifuge products and dry screw machines, which can reduce production and operating costs for automotive companies.

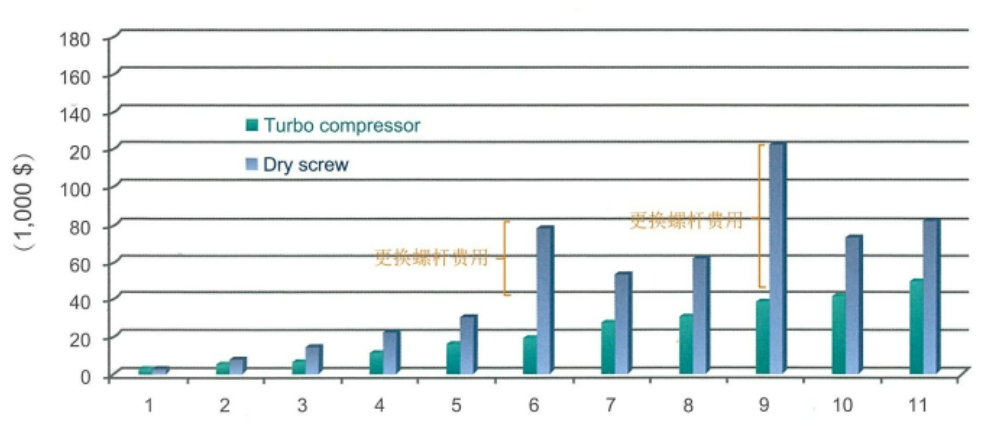

③ Lower costs and strong after-sales support:

The long-term operation of the air compressor requires continuous maintenance and after-sales support services. Automobile companies should ensure that suppliers can provide timely maintenance support, spare parts supply, and technical guidance to ensure the normal operation of air compressors. IHI-Sullair centrifugal air compressor is easy to maintain and low-cost; Adopting horizontally split gearboxes, bearings, and shaft seals for easy maintenance; The cooling water flows inside the pipes and the air flows outside the pipes, making it less prone to scaling. At the same time, the titanium alloy material of the impeller is also more corrosion-resistant, making it easier to clean. We have a professional after-sales service team to help you solve problems and ensure the long-term stable operation of the centrifuge product you purchased.

IHI-Sullair can provide automotive companies with air compressor products that meet the technical requirements of vehicle manufacturing, and provide corresponding maintenance services and professional after-sales support. In recent years, IHI-Sullair has provided high-quality, efficient and energy-saving centrifugal air compressor products to many well-known domestic car companies, and continues to provide technical support.

Choosing IHI-Sullair, we will ensure your stable production with first-class product quality and professional technical team, and create more economic value for you. In the future, we will continue to root in China, empower China's industrial development with high-quality products and services, and contribute to the sustainable development of China's social and economic development.